Leveraging Multi-Agent Systems for Supply Chain Optimization

By 2030, the market for AI in supply chains is estimated to reach $41.23 billion with 38% Compound annual growth rate (Data Library Research, AI in Supply Chain), with the promise of improved efficiency and the ability to manage complex logistics operations. Supply chains equipped with AI have shown substantial effectiveness improvements, over 67% more effective than traditional systems in terms of risk reduction and cost optimization (Global AI in Supply Chain Management Market Report).

Supply chain management represents one of the most complex coordination challenges. With global networks of suppliers, multiple transportation modalities, varying warehouse capacities, and fluctuating consumer demand, optimizing a supply chain requires balancing countless variables simultaneously. Traditional solutions have relied on centralized optimization algorithms that struggle to adapt to real-time changes and often fail to capture the full complexity of modern supply chains. This is where multi-agent systems offer a revolutionary approach.

The Evolution of Multi-Agent Architectures in Supply Chain

Multi-agent systems (MAS) consist of several autonomous agents working collectively toward common goals, with each agent possessing specific capabilities, knowledge domains, and responsibilities. Unlike traditional monolithic AI systems, multi-agent architectures distribute intelligence across specialized components, creating systems that are more robust, adaptable, and capable of handling complex workflows.

According to recent research published in The American Journals, MAS coupled with Machine Learning can significantly enhance supply chain resilience through decentralized decision-making, where each agent is responsible for a particular supply chain activity but employs real-time data from ML models to streamline operations. This decentralization enables resilience in supply chains that experience events such as demand variability and transportation disruptions—a critical capability in today's volatile market environment.

The Challenge of Modern Supply Chains

Today's enterprises face unprecedented supply chain complexity. According to Deloitte's 2025 Manufacturing Industry Outlook, manufacturers are increasingly investing in digital technologies to address elevated material and labor costs, ongoing skills gaps, and potential disruptions from geopolitical factors.

As supply chain pressures have abated due to multi-factor regional disruptions, companies have shifted their strategy from a primary focus on efficience and cost reduction to a new emphasis on resilience and risk mitigation. Techniques such as diversifying supply chain routes and sources, focusing in strategic partnerships, and building internal real-time controls, audit and governance, are helping companies achieve this goal.

Multi-Agent Systems: Collaboration and Orchestration

Multi-agent AI systems involve multiple AI Agents working together to achieve a common goal. Typically, these systems consist of standard-task agents (e.g., logistics, route planning, cost optimization, data management and monitoring agents) coordinating specialized-skills and tools (e.g., data validation, risk estimation or image interpretation). This architecture enables:

- Complex Workflow Orchestration: Multi-agent systems can orchestrate complex workflows in minutes, significantly reducing the time and resources required for complex tasks in at least one order of magnitude (from hours or even days).

- Enhanced Productivity: By working collaboratively, agents can plan and execute complex workflows based on clear objectives, constraints and context.

- Improved Accuracy: Validator agents can interact with manager agents to test and improve output quality and reliability.

- New Levels of Machine-Powered Intelligence: When agents specializing in specific tasks work together, new levels of machine-powered intelligence are made possible.

These multi-agent systems often employ hierarchical structures, where higher-level agents supervise and direct worker and delivery agents, ensuring alignment with overall objectives, particularly effective in large-scale settings like warehouse operations.

C3 AI's Multi-Hop Orchestration Approach

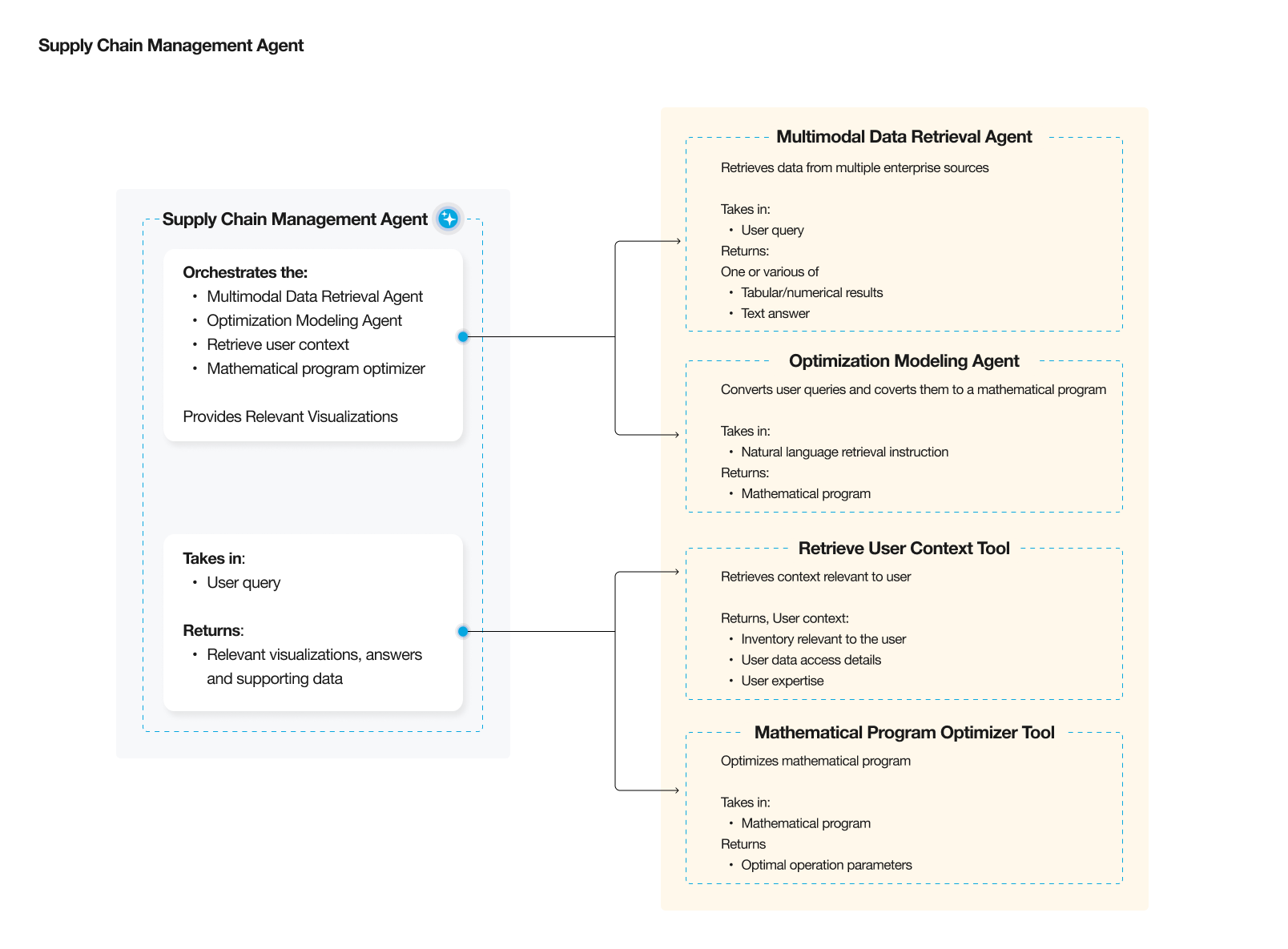

C3 AI's supply chain management agent addresses these challenges with a multi-agent system powered by advanced AI techniques. These agents combine expert-driven logic, real-time data, and advanced modeling to transform supply chain operations.

This framework applies to Supply Chain Management and Optimization using specialized adaptive agents with constraints for Uncertainty Handling, User Interaction and Real-Time Adaptation (Challenges in Multi-hop Reasoning).

The multi-agent orchestration approach includes (C3 AI Orchestration Agents):

-

Expert-driven logic: In the form of Expert-Defined Business Rules, Adaptive Demand Forecasting Based on Expert Insight, Custom Inventory Buffering and Safety Stock Strategies, Supplier and Vendor Optimization, Transport and Routing Decisions as well as Compliance and Sustainability Tracking.

-

Orchestration Agent: Acts as the main controller, converts user requests into instructions for other agents, coordinates interactions between data retrieval, optimization, and analysis. Manages interaction across the multi-agent system. Additionaly it Incorporates specific SME-defined rules and priorities, retrieves data and feeds the model with supply chain metrics, visualizes results and performs "What-If" analyses.

-

Specialized Agents:

-

Multimodal Data Retrieval Agent: Gathers supply chain data from various sources based on user requests to be used as input into the optimization model. It connects requests with key metrics like inventory levels, supplier lead times, demand forecasts, and transportation costs.

-

Optimization Modeling Agent: Builds optimization models for supply chain operations based on business rules and priorities. It converts these rules into mathematical constraints, focusing on inventory optimization or route planning to deliver recommendations that align with the organization's goals.

-

C3 reports using their AI’s supply chain management agent with a multinational retailer, obtaining a 20% reduction in stockouts, 15% decrease in transportation costs as well as sustainability improvements aligned with environmental goals (c3 SCM results).

Key Supply Chain Use Cases for Multi-Agent Systems

Multi-agent systems offer a wide range of applications within the supply chain. Here are some specific use cases:

Demand Forecasting and Inventory Management

Demand Forecasting Agents can analyze historical sales data, market trends, and real-time demand signals to predict future demand accurately. According to LogisticsViewpoints, these agents can leverage machine learning algorithms to achieve significant improvements in forecast accuracy compared to traditional methods.

Inventory Management Agents can monitor stock levels in real-time and compare them with demand forecasts, optimizing inventory levels and preventing overstock or stockouts. This capability is crucial given that the National Association of Manufacturers reports that 44% of manufacturer leaders say the amount of data they collect has doubled in the past two years and expect it to triple by 2030.

Logistics and Transportation Optimization

Logistics Optimization Agents can analyze transportation networks, weather patterns, and other variables to optimize routes and reduce costs. With real-time data processing, they can continuously monitor conditions and reroute shipments when necessary.

Real-Time Shipment Tracking Agents can provide updates on shipment status, helping businesses and customers plan accordingly. This is particularly important as average lead times for production materials have shown significant improvement since their peak in 2022 but remain stubbornly higher than pre-pandemic levels.

Warehouse Automation and Resource Allocation

Warehouse Automation Agents can perform tasks like sorting, picking, and packing, significantly speeding up operations. According to Imaginovation, in 2025, human-robot collaboration will remain a significant trend, mainly through collaborative robots (cobots). Cobots are designed to assist with heavy lifting, repetitive and precision tasks, and handling objects in hazardous environments, boosting productivity and ensuring safety.

Resource Allocation Agents can allocate resources dynamically—e.g., during peak hours, optimizing warehouse operations. This is particularly important as manufacturers continue to face higher costs: The producer price index for input materials and components seems to have stabilized but remains high, while total compensation, which includes wages and benefits, has continued its upward climb.

Implementation Strategies for Enterprise-Scale Multi-Agent Systems

Implementing a multi-agent system for supply chain optimization requires a methodical approach covering the following stages:

1. Requirement Analysis

Define stakeholder expectations and system requirements through extensive workshops with key personnel across the organization.

2. System Analysis

Identify key roles, environmental factors, and inter-agent interactions to ensure comprehensive coverage of all supply chain functions. This aligns with the trend toward data-driven decision-making, which is expected to intensify by 2025, with businesses investing in advanced analytics platforms, data infrastructure, and real-time processing capabilities.

3. Architectural Design

Establish the organizational structure and rules governing agent interactions, ensuring clear communication protocols between agents. This is particularly important as communication overhead can slow down workflows. Implementing scalable communication strategies that are efficient and minimal prevents computational overload as the system scales.

4. Detailed Design

Develop specialized agent models and define specific services each agent will provide, with clear interfaces between them. This supports the trend toward smart operations, which is likely to continue in 2025 given the elevated material and labor costs, an ongoing skills gap, and potential disruptions from geopolitical factors.

5. Implementation Design

Create protocols for agent communication and knowledge representation, ensuring seamless information flow. This methodical approach ensures the autonomous system is built on a solid foundation, capable of addressing the complex dynamics of the retail supply chain.

Akira AI's Multi-Agent Architecture for Supply Chain

Akira AI has developed a comprehensive multi-agent architecture specifically for supply chain optimization:

-

Predictive Agent: Analyzes past and current data to forecast demand, anticipate disruptions, and identify trends, allowing businesses to make informed decisions and mitigate risks.

-

Prescriptive Agent: Offers actionable recommendations to optimize routes and adjust inventory levels, ensuring the supply chain operates efficiently and cost-effectively.

-

Integration Agent: Ensures smooth communication across various parts of the supply chain by integrating data from different sources like internal systems, external markets, and inventory updates, creating a cohesive flow of information.

-

User Dashboard Agent: Provides real-time insights through dashboards and reporting tools, enabling users to track key metrics, shipments, and performance, empowering them to make timely decisions.

-

Monitoring Agent: Continuously collects data on inventory, equipment status, and environmental conditions, ensuring that the system is always up to date and that potential issues are addressed quickly.

These agents work together seamlessly to optimize the entire supply chain process, improving decision-making and operational efficiency.

Overcoming Implementation Challenges

Throughout implementation, organizations typically encounter several key challenges:

Agent Overspecialization

While specialization is important, agents that are too narrowly focused can create bottlenecks. Ensuring each agent has enough breadth to handle variations in its domain prevents single points of failure.

Communication Overhead

Too much inter-agent communication can slow down workflows. Implementing scalable communication strategies that are efficient and minimal prevents computational overload as the system scales.

Cascade Failures

When one agent fails, it can trigger failures downstream. Multi-agent systems should be designed to prevent propagation of faults and be self-recovering, significantly enhancing resilience.

Decision Deadlocks

Multiple agents might wait for each other to make decisions. Implementing clear authority hierarchies and challenge-response-contract schemes helps resolve conflicts quickly and efficiently.

Future Directions in Supply Chain Automation

Building on the success of current implementations, organizations are expanding their multi-agent systems to include:

Enhanced Supplier Integration

Extending agent collaboration to key suppliers creates a more integrated supply chain ecosystem. This approach aligns with the broader trend toward hyperautomation, which Imaginovation identifies as a key automation trend for 2025.

Sustainability Optimization

Adding carbon footprint considerations to optimization objectives is becoming increasingly important. According to Deloitte's analysis, industrial companies are maintaining their focus on reducing the emissions of their products, and customers remain intent on lowering their operating emissions.

Product Lifecycle Management

Incorporating new product introductions and end-of-life considerations further enhances the system's ability to manage inventory effectively across the entire product lifecycle.

Conclusion: The Future of Supply Chain Intelligence

As multi-agent systems continue to evolve, they promise to transform entire business functions through autonomous resilient process management. The agentic approach enhances human teams with specialized roles that bridge gaps of expertise and help coordination between high-performing teams highly focused on specific tasks with parallel dependencies being performed or even managed by autonomous agents.

Multi-agent systems allow real-time coordination across global supply chains, enabling adaptive responses to disruptions - a critical capability in today's volatile business environment.

According to SYP's analysis of digital transformation trends, as we approach 2025, the landscape of digital transformation continues to evolve, driving innovation, enhancing operational efficiencies, and creating new business opportunities across various sectors. Multi-agent systems are positioned to play a crucial role in this transformation.

By embracing multi-agent systems, enterprises can unlock new levels of automation, efficiency, and problem-solving capability—transforming how we approach complex supply chain challenges in the AI era.

References

- [1] The American Journals - Enhancing supply chain resilience with multi-agent systems and machine learning

- [2] Deloitte - 2025 Manufacturing Industry Outlook

- [3] Imaginovation - Top Automation Trends 2025: Transforming Industries

- [4] LogisticsViewpoints - Unlocking Supply Chain Potential with AI Agents and Multi-Agent Workflows

- [5] SYP - Key Digital Transformation Trends Shaping Industries by 2025

- [6] Akira AI - AI Agents: Re-Envisioning Supply Chains for Industrial Automation

- [7] LinkedIn - Navigating The Adoption of Agents in 2025

- [8] LinkedIn - How Intelligent Agents Will Transform Supply Chains in 2025

- [9] Kardex Remstar - Warehouse Automation Trends for 2025

- [10] FreightWaves - How automation is solving logistics' biggest problems in 2025

- [11] LinkedIn - Supply Chain Roadmap 2025 – The Evolution Of Automation

- [12] ZingFlow - Supply chain automation guide for 2025

- [13] Data Library Research - AI in Supply Chain

- [14] SAP - AI, Sustainability and Resilience Top Supply Chain Trends for 2025

- [15] GEP - Meet Your New Procurement Team: How AI Agents Are Changing the Game

- [16] Andreessen Horowitz - RIP to RPA: The Rise of Intelligent Automation

- [17] McKinsey & Company - Is industrial automation headed for a tipping point?

- [18] Research and Markets - Global Artificial Intelligence in Supply Chain Management Market Report

- [19] c3.ai - Understanding Multi-Hop Orchestration Agents

Ready to build your own multi-agent workflows? Contact our solutions team for a personalized consultation.